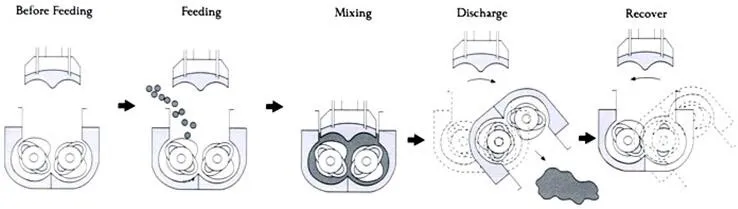

High efficiency, energy saving and saving occupied space. Electric parts adopt ABB or US Brand, that will ensure good performance.Ĥ.Hydraulic pressure tilting mechanism with the advantage of fast discharging materials and 140 tilt angle. Under the pressure of hummer, the two rotors shear, extrude, and stir rubber (plastic) materials at different rotational speed in the pressure-tight mixing. 3. The machine PLC control system adopts Mitsubishi/Omron. Dispersion Kneader Machine Motor, reducer adopts hardened tooth surface gear, that has low noise and can save 20% electricity or power and has a long service life. The chamber, rotors and piston ram are all jacketed structure for the ingoing of steam, oil and water for heating and cooling to suit the various requirement for the process of mixing and plastication.Ģ. Kneader machine consists of body welded with high quality steel plates and two pieces of side plates. They are also used for material flow tests. Steel Cord/ Multi-fabric Conveyor Belt Lineġ. They are ideal for rubber insert, moulding and encapsulation of small electonic components, medical parts and epoxies, silicones and other thermosets.Conveyor Belt Green Belt Molding Machine Line.Solid Tire Mold Clamping & Unclamping Press.Four-roll Rubber Calender (divided into single drive and four-drive).

Three-roll Rubber Calender (divided into single drive and triple-drive).Two-roll Rubber Calender (divided into single drive and double-drive).3.The hydraulic dispersion kneader machine has less noise than pneumatic. Dust/ Fume Collecting and Disposal System The pressure of the hydraulic dispersion kneader is more balanced and stable working compared with the pneumatic type dispersion kneader,which can effectively improve the dispersion effect of various mixture materials and enhance the quality of the rubber&plastic compound.Intelligent Mixer Feeding and Micro-Control System.Automatic multi-station dosing system for minor ingredients.

0 kommentar(er)

0 kommentar(er)